Production Cost (p/Slab)

At Bamby Stone, our team strives to simplify all calculations, ensuring that our clients can easily estimate their production costs. We provide measurements for every slab in our collection page below each stone slab. By comparing your project drawings with our slab sizes, you can determine the total size required for your project. If one slab suffices, only one production cost and one installation cost will be added to the slab cost.

$3,500.00 – $4,000.00

Bamby Stone Edge Profiles

Modern CNC control technology enables the creation of precise stone benchtop profiles that would be difficult to achieve manually. This technology also makes detailed edge work more affordable compared to doing it entirely by hand. At Global Marble & Granite, we always perform hand touch-ups on edges after the CNC stage to ensure a perfect finish. In recent years, simple square edges with a pencil round have become popular, such as the T20 and T40 or their mitred versions. All our square edge profiles feature a pencil round finish, which is less prone to chipping than arris, bevel, or chamfer edges. We recommend a minimum R5 radius for all natural stones, such as marble or granite. All external corners will be rounded to match the edge detail or according to customer requests. Above in pictures is a selection of the most commonly used edge profiles for stone benchtops.

Additional information

| Edge Profiles | T20 – Square Pencil, V20 – Bullnose, 40mm – Mitred Returned, 40mm Square Pencil Round, 40mm Mitred, AM40, 40mm Sharknose, O20SQ, 40mm Bullnose, 60mm Mitred, 60mm Mitred Return, 80mm Mitred, 80mm Mitred Returned, 100mm Mitred, 100mm Mitred Return, Waterfall |

|---|

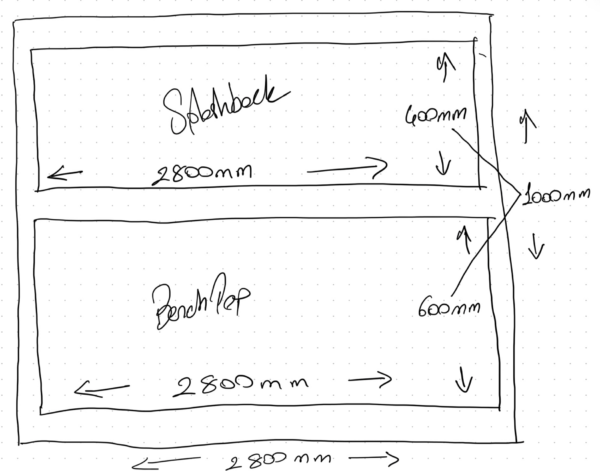

Based on this drawing you need a slab size of 2800mm by 1000mm to finish this project with one x Slab + one x Production cost + one x Installation cost. Now if you;

Based on this drawing you need a slab size of 2800mm by 1000mm to finish this project with one x Slab + one x Production cost + one x Installation cost. Now if you;